© 2025 Fresh Trading Limited. All rights reserved. innocent and the Dude logo are registered trademarks of Fresh Trading Limited.

climate changers

on our way to carbon neutral

Unless you like living under rocks or burying your head in sand, you'll probably know that we're bang in the middle of a climate emergency. Climate change is one of the biggest challenges we face and collectively, we need to do everything we can to stop it. That's why, along with hundreds of other B Corps, we've committed to being carbon neutral by 2030 (if not before).

To reach that goal, we're trimming out carbon from every part of our supply chain and building one of the most sustainable factories the world has ever seen. Based over in Rotterdam, it's going to take millions of miles off the road, waste fewer precious resources and run on 100% renewable energy. Read on to find out what else we're doing to hit our 2030 target.

the story so far

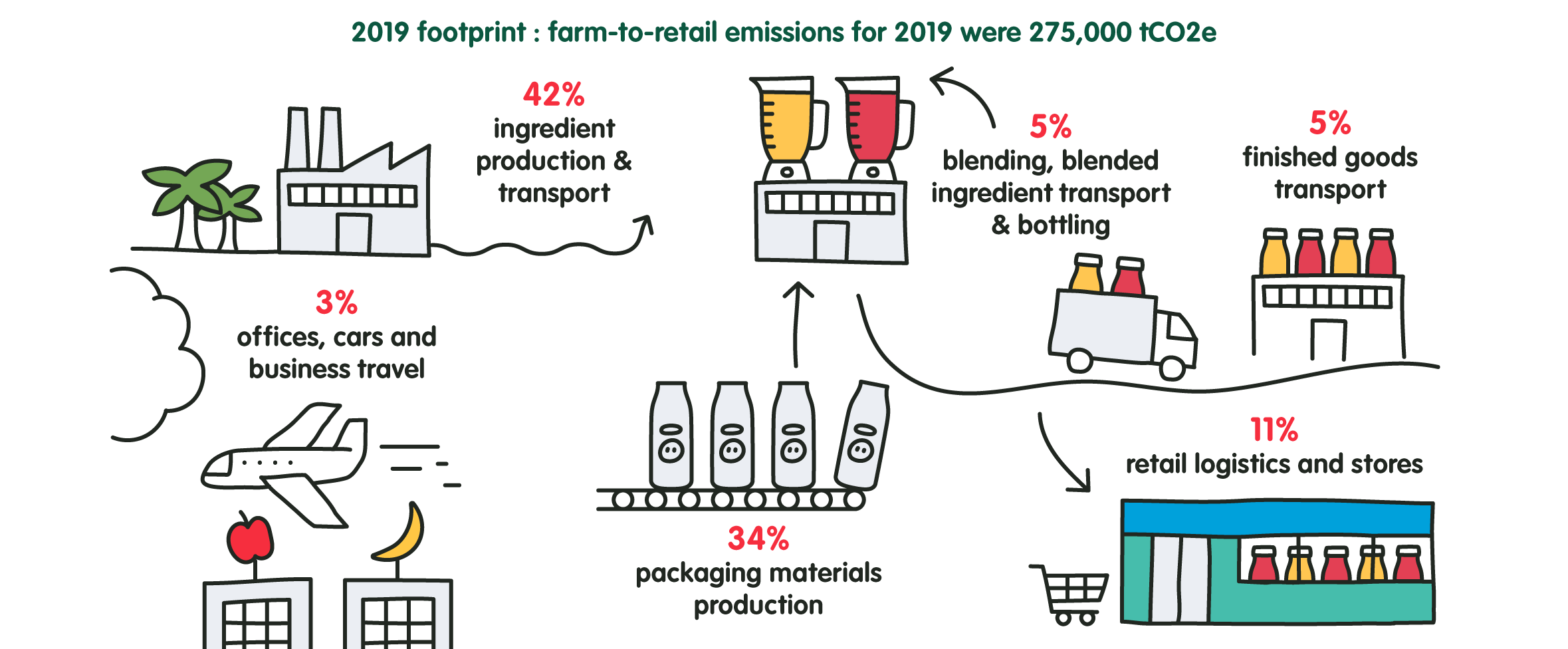

where our carbon comes from

how we're balancing the rest

By doing all the stuff we've talked about above, we're reducing the amount of carbon it takes to make our drinks. But until we've worked out how to make a drink without producing any carbon at all, we'll need to balance the rest through something called carbon offsetting.

Carbon offsetting is easiest to explain with a glass of water and a sponge. If we imagine our annual carbon emissions as a glass of water, reducing our emissions is like putting less water in the glass and carbon offsetting is like dipping a sponge into it until all the water has been soaked up. The most popular way to soak up carbon emissions is by planting trees, which capture and store carbon as they grow. Another way is to invest in initiatives that avoid greenhouse gases in the first place. For example, investing in greener energy options that replace fossil fuels or projects that conserve the world's natural 'carbon sinks', like tropical rainforests or peat bogs.

Between now and 2023, we'll be working with leading carbon offsetters and tree planting experts to create our very own climate action plan. The plan will invest in local initiatives (like tree planting and peat bog conservation) and more global ones that protect or regenerate rainforests in areas of the world that are the most impacted by climate change.